Principle

A sand trap provides for the quick removal of settleable (sand) particles from the water, in order to prevent damage to mechanical components in the water treatment plant. A sand trap is usually carried out as a concrete gutter, where the waste water flows through while sand particles settle. In order to obtain an enhanced separation of sand and organic particles an aerated sand trap is sometimes applied. A combination of a sand trap and a grease trap is also possible. The removal of the sand particles is done either mechanically and continuously through scrapers and a drainage pipe, or discontinuously by manual removal.

Applications

A sand trap is often used in domestic wastewater treatment and also occurs frequently for treatment of wastewater from mining and processing of vegetables and potatoes. The principle of the sand trap can also find an application in treatment of polluted rain water. The separated sand stream can optionally be further dewatered by means of a sand classifier.

Example of realisation

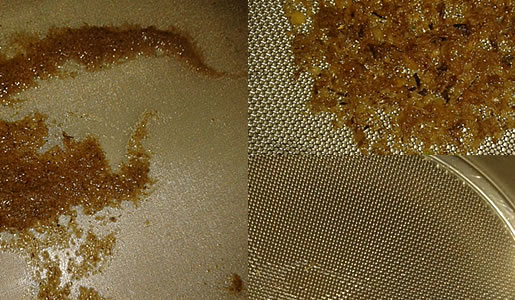

Sand trap in a sugar beet processing plant.

Approach Trevi

The sizing of the sand trap is determined on the amount and settling speed of the sand particles and the flow rate, taking into account sand accumulation or sand storage.

In order to verify the applicability of a sand trap, settling tests and sieve tests are performed on a representative effluent sample. Based on the results, the sand trap is dimensioned. Since a sand trap is characterized by low automation, minimal maintenance and doesn’t require additives, it is a simple and relatively cheap installation for primary purification.

The identification of the size of particles to be separated is performed by a standardized sieve test with sieves with different mesh sizes.